Do Electric Vehicles Require Lubricants? Our R&D Engineer Answers

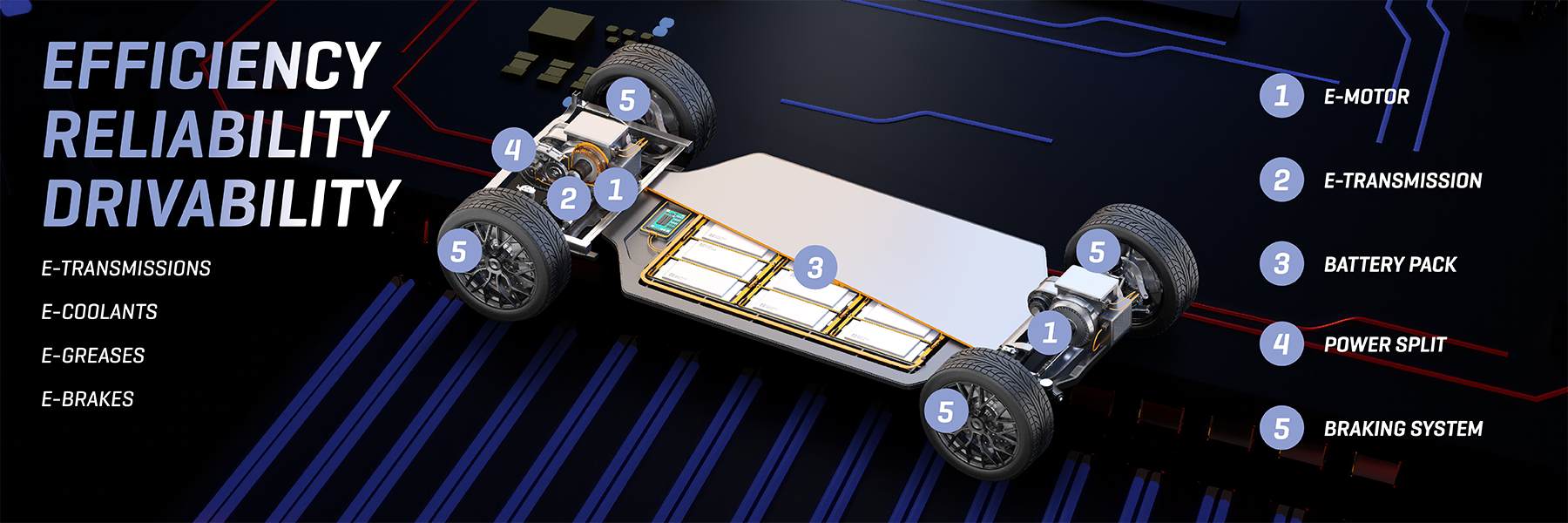

Lubrication is a tried-and-true necessity for keeping petrol and diesel engines running smoothly. But with the surge of electric vehicles (EVs) hitting the roads, you might be wondering: Are lubricants still needed? And if so, what’s required to keep these electrified powerhouses in top form?

The days of Tesla dominating the EV market are long gone. Traditional automotive giants like Ford, BMW, and Volkswagen are now doubling down on their own electric offerings, as well as new actors emerging from China such as BYD or NIO, and the market is only expanding. Since the launch of Tesla's Model S, EVs are no longer a niche—they’re the future, fueled by the need for cleaner, more sustainable transportation and stricter environmental (emission) regulations.

As EVs continue to gain ground, workshops everywhere are getting EV-savvy, training and certifying technicians to service the new generation of electric and hybrid vehicles. Champion Lubricants is right there with them, offering E-PULSE, a full suite of EV-specific products—designed to meet the unique demands of electric and hybrid vehicles.

We caught up with our R&D Engineer, Bert De Haes, to get the inside scoop on why lubricants still play a vital role in electric vehicles and how Champion is leading the charge.

“With more EVs entering the aftermarket, understanding the fundamental similarities and differences with traditional powertrains is crucial. Just like internal combustion engine (ICE) vehicles, electric vehicles require high-quality lubricants for optimal performance and longevity. While some elements of servicing may differ between the powertrain architectures, lubrication is certainly essential for both.”

Many assume that with fewer moving parts, EVs require less lubrication. That, however, is not correct.

“The high instantaneous torque and high speeds of e-motors mean that the stresses on components like gears, shafts, and bearings can be much higher than ICE-vehicles. This extends to all mechanical driveline components, which must be developed to handle the significant jump in torque.”

Materials, longevity, & conductivity

Bert De Haes is quick to point out that there are also material challenges in developing lubricants for EVs.

“EVs employ materials that have not traditionally been seen in automotive transmissions; more plastics are used for insulating purposes, or in lightweight replacements of traditional metal components, and an additional amount of copper is incorporated in wiring, power electronics and heat sinks. Depending on the application, lubricant in an EV might come into contact with a number of materials, including steel, aluminium, copper, rubber, and plastic. Ensuring compatibility with a wide range of metals and non-metals to avoid degradation is essential to long-term functionality.”

Another consideration is maintenance intervals. Lubricants designed for use in EVs need to perform at a high level across service intervals as high as 32,000 kms or 24 months.

“Some manufacturers and motorists seek to extend their service intervals. We factor this into our lubricant formulations, avoiding the risk of a lubricant breaking down or experiencing substantial performance loss during its service life.”

There is also the simple fact that EVs have high-voltage electrical systems, some even as high as 800 Volts.

“For EVs, safety around the electrical system is essential. Depending on the lubricant and its role, balancing its electrical conductivity can mean the difference between current leakage and charge accumulation. In many EV designs, the e-motor and electronic controls may be immersed in the lubricant, or at least come into contact with it. Dielectric* properties must therefore be optimised for high voltage applications and the associated temperatures.”

*A dielectric is a material that resists the flow of electric current, acting as an insulator. In an electric field, it stores electrical energy by polarizing rather than allowing current to pass, because it has no freely moving charges like those in conductive materials.

Efficiency & Performance

Just like in ICE vehicles, quality lubricants can make a significant difference in efficiency. In the case of EVs, this means more mileage.

“For EV applications, low-viscosity lubricants are used for faster warm-up and reduced energy usage. In turn, this minimizes losses and increases vehicle mileage– a very important consideration for EVs. Unlike conventional transmission fluids, EV lubricants must also consider all the previously mentioned factors simultaneously – it certainly gets complex !”

EV Specialist Lubricants

When selecting EV lubricants, always follow manufacturer guidelines and select a high-quality product that meets the required specifications. Champion Lubricants offers a comprehensive range of lubricants and fluids: E-PULSE. Each product is specifically designed for EVs – including BEVs, PHEVs, and FCEVs – by Champion’s in-house R&D team.

When it comes to EV lubrication, E-PULSE offers:

- Next-generation e-motor and transmission fluid for ‘wet’ motor battery electric vehicles.

- Optimised dielectric properties for high-voltage applications

- Excellent wear protection while also being ultra-low viscosity.

- Premium E-DCT (Dual Clutch) transmission and reduction gear fluid for electrified transmissions where wet clutch and synchronizer performance is required.

- Offers excellent shear stability and extended service life.

- Full synthetic lubricant formulated for automatic transmissions in EVs (e-ATF).

- Provides excellent frictional durability, smooth shifting, superior performance and an extended service life.

- High-performance lithium complex synthetic grease for E-motor bearings.

- Contains antioxidants, corrosion inhibitors and EP/AW additives based on bismuth technology for enhanced resistance to vibrations and shock loads.

- Lithium complex grease for wheel bearings

- Provides excellent wear resistance and load capacity in both high- and low-temperature applications.